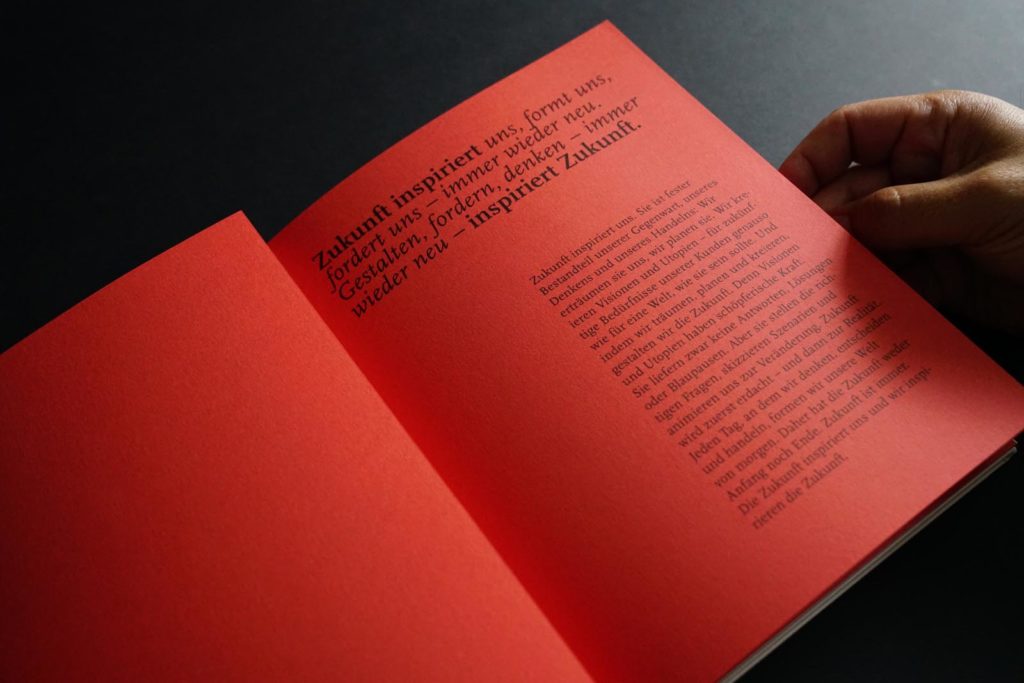

When you hold the Melitta annual report in your hands, it's hard to know where to start with the amazement and delight. Laser punching, fold-outs, various paper changes and a thread-stitched Swiss brochure with an open spine - all the stops have really been pulled out here. Nevertheless, the annual report is not only impressively produced, but also an all-round sustainable product. The Munich-based graphic design studio klee.steinberger checked every component of the annual report for its environmental compatibility, from the paper to the adhesive and the finishing. The result is truly impressive and shows what is possible when designers consistently implement the topic of sustainability in their designs. We spoke to Claudia Klee and Vit Steinberger about this unusual project.

Sustainability played a major role in the annual report, to what extent did it also influence the design? Did you first develop a visual concept and then look at how it could be implemented in an environmentally friendly way or did sustainable production influence the design?

The Melitta Group annual report should not only report on the topic or projects, but the print version itself should reflect the company's sustainable way of thinking and doing business and be implemented as sustainably as possible in all facets.

Environmental impact, benefits and appreciation/response rate should be in the best possible relationship to each other. The print product, the design and the careful project planning were geared towards this goal.

That's why it was a ping-pong game from the initial idea to dispatch. The design of the report and production planning had to interlock from the very beginning and be thought of as an overall process. Sustainable, resource-conserving production and aesthetic design should push each other, not cut back on each other. It is precisely because you no longer have the full range of finishing options at your disposal that new ways of thinking open up. The process becomes more focused, as does the product. It was liberating and exciting to be able to work with reduced possibilities.

Can you tell us something about the paper?

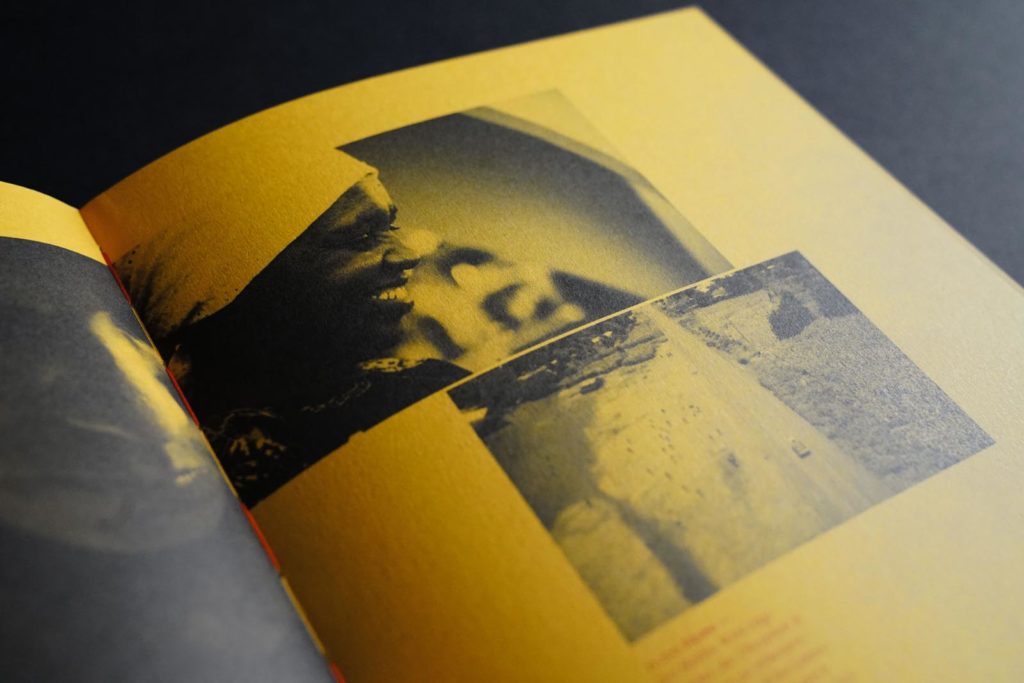

The decision to use Extract Paper had by far the greatest influence on the design, especially on the use of color. By using different colored papers, we deliberately avoided color in printing and were able to reduce the use of printing inks. However, the decisive criterion was that it is a paper made from secondary fibers, as well as the distant connection to coffee and the contribution to solving the problem of mass-produced coffee-to-go cups. Consistently producing sustainably is much more than just using recycled paper, although this has the greatest relevance for the environment. Our considerations and decisions ranged from design, format adaptation, sensible page count, materiality, production and processing with the environmental printing company Ulenspiegel - to CO2 efficiency, benefits and lifespan of the annual report medium in general and as a means of communication with multi-layered messages for the Melitta Group in particular - to logistics/transport routes, reuse of waste paper and offcuts. Above all, the high-quality print version should be an inspiring statement by the Melitta Group for a sustainable future and remain on the bookshelf for a long time.

Which papers exactly did you use and how were they printed or finished?

Inside cover material: Extract Paper from G.F Smith/Römerturm, 130g/sqm, 2/2-color print (black + P485)

Poster material: Recystar (now EnviroNatur) 100g/sqm, 2/2-color print (black + P485)

Cover outer material: Gmund Colors Matt 71: 480g/sqm, laser cut, blind embossing

The Melitta annual report is very elaborately produced, what was actually the hardest nut to crack in terms of production?

The hardest nut to crack was the book jacket with integrated pocket. This had to be made from one piece so that we could dispense with glue and unnecessary production steps and at the same time have the greatest possible stability. It also needed to be a certain height to ensure easy handling with the poster inserted. We experimented a lot, together with Ulenspiegel Druck and Stigler.

You have certainly learned a lot about sustainability from this project, what were you not aware of before?

That there are far fewer technical innovations for resource-saving production than expected. The greatest potential lies in the material paper and ink. (The CupCycling technology was developed for the production of Extract Paper. This solution required a unique collaboration between consumer, recycler and paper manufacturer). And, of course, the collaboration with an environmental printing company like Ulenspiegel. We were also surprised that although dispersion glues, i.e. water-based glues, are available, they can only be used in combination with thread sewing without the glue dissolving. They cannot be used for pure adhesive binding.

What did you enjoy the most, what are you particularly proud of?

When one thing leads to another and everything makes sense together - linking the motto with production and material and with digital media. Thinking and implementing projects and topics in this way is a personal concern for us - it was fun.

And above all, we were able to work with the Melitta Group and our partners to implement the project with this objective so consistently - through many discussions, tinkering and experimenting and carefully considered decisions.

The basis: sustainable extract paper

G.F Smith's colorful Extract paper made from recycled coffee-to-go cups was used as the basis for the Melitta annual report. With the help of James Cropper's CupCycling technology, 90 percent of a disposable cup can now be converted into FSC®-certified paper fibers. The remaining ten percent of plastic is processed into other products so that no waste is produced ("zero waste"). Thanks to the innovative CupCycling technology, each sheet of Extract with a grammage of 380 g/m² contains at least five recycled coffee-to-go cups.

Römerturm Feinstpapier is the exclusive distribution partner for Extract from G.F Smith in Germany. Extract is available in grammages of 130 g/m² and 380 g/m² from just one sheet. Further information at www.roemerturm.de